60 Years „Made in Germany“

1946Foundation of TREPEL

Mr. Ingo Trepel was the original founder of the company „TREPEL“. He established the company directly after World War II, during the reconstruction phase of Germany. Ingo Trepel began with the reprocessing treatment of machine tools. He attended the first exhibition/trade fair where he established a business for the overhauling of machines in Wiesbaden.

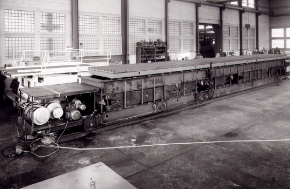

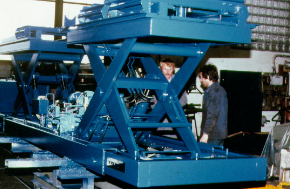

1956Lifting tables and scissor lifts

During this period the first lifting tables and scissor lifts were developed, still being integral part of automation installations. Main focus at that time was the processing of flake boards and vessel platforms for roll on/roll off movements. The fast growing business called already at that time for scissor lifts with a capacity from 500 kg to 500 tons.

1963Catering vehicles

During this time the Boeing 747 was constructed and the question arose: How could an aircraft with a loading height of 5 meters best be provided with catering for the passengers? This called Ingo Trepel into action because of his scissor systems offering a solution: The catering vehicle era was born.

1973First cargo high loaders in Europe

After Ingo Trepel had solved the catering problem in the middle of the sixties, he started building the first cargo high loaders in Europe. Forklifts that had been used up to this time for the loading and discharging of cargo were no longer accepted because of numerous damages they caused to the aircraft. The time for the first 12 ton loader had come. During the following years numerous cargo high loaders with different capabilities were added to this product line.

1985PHB Weserhütte AG

Ingo Trepel retired and the company was absorbed by the „PHB Weserhütte AG“. It was decided that two of the product lines – the lift / load technique and the airport division – should continue business in Wiesbaden. The stage-building technique and the freight-handling systems were closed.

1991New production halls in Tauberbischofsheim

Meanwhile, the airport sector grew and was relocated to Tauberbischofsheim for lack of space. In the immediate vicinity to the sister company “MAFI Transport-Systeme GmbH” new production halls were built on greenfield site, making sure that enough space was available to build the cargo high loaders. With the assistance of MAFI the location established itself very well and even started producing the first cargo high loaders independently of customer orders.

1996Foundation of TREPEL Airport Equipment GmbH

In 1996, the whole airport section became autarkic and the “TREPEL Airport Equipment GmbH” in Tauberbischofsheim and Wiesbaden was founded. By standardizing the airport products and the decision to produce independently of orders TREPEL managed to realize quick delivery times and combine these with high-class quality.

2003World leadership of sold cargo high loaders

For the first time TREPEL achieved world leadership referring to the number of sold cargo high loaders for civil usage. The associates decided to invest further into the future business and expanded the production facilities in Tauberbischofsheim.

20063,000 delivered units

With over 3,000 delivered units, TREPEL looked forward to a bright future and decided to use its know-how to create and launch new GSE products, such as the pallet/container transporter TRANS 70.

2008New flagship CHAMP 350

TREPEL intensified its engineering efforts and not only further developed and improved its existing range of loaders but also introduced new products into the market: The main deck loaders got a new flagship, the CHAMP 350, which is the most capable loader in the world with a loading capacity of 35 tons on each of its two platforms. TREPEL also developed a new towing tractor: the TAE 20 electric. The innovative technology and design of the TAE 20e have very successfully opened a whole new market for TREPEL.

2009Entering the market of conventional aircraft tractors

TREPEL entered the market of conventional aircraft tractors and launched the CHALLENGER 700 during the ”inter airport europe” show in Munich. This new, innovative aircraft tractor is capable of towing a fully loaded A380.

2009Introduction of the first CHAMP 70e

The first electric CHAMP 70W with lithium battery was exhibited at the ”inter airport europe” show in Munich. Since then, the electric version of the CHAMP 70 has successfully established itself as a “zero emission” machine. The electric 7t loader is operating daily in countries as various as Sweden, Qatar, Spain and Germany.

2010New aircraft tractors to handle mid-size and small aircraft

TREPEL continued its offensive in the aircraft tractor market. Fostered by the success of the CHALLENGER 700, TREPEL launched two new aircraft tractors designed to handle mid-size and small aircraft, the CHALLENGER 430 and CHALLENGER 160.

2015100th CHAMP 350 sold

The 100th CHAMP 350 was sold to Sheremetyevo Airport. The handover of the 100th 35 ton loader to Sheremetyevo Airport was celebrated in our factory in Tauberbischofsheim. The CHAMP 350, first introduced in 2007 at the ”inter airport europe” show in Munich, is one of the most powerful main deck loaders in the world and characterized by its lifting capacity of 35 tons on both platforms, the ideal device for the handling of heavy loads.

2016500th CHAMP 140 sold

The 500th CHAMP 140 was sold to Portground Leipzig. The handover of the 500th 14 ton loader to Portground was celebrated in our factory in Tauberbischofsheim. The CHAMP 140 is the workhorse amongst the main deck loaders and has been delivered to more than 100 countries.

2016Acquisition of towbarless technology

Acquisition of the towbarless technology from GHH in June 2016. The launch of the first towbarless aircraft tractor is planned for 2019. In the near future, Trepel will be in a position to offer its customers the whole range of aircraft tractors, conventional as well as towbarless. All kinds of aircraft moving, from pushback to high speed maintenance towing, can be performed by a TREPEL tractor.

2017Opening of the Visitor Center

Customers as well as suppliers are now welcomed in newly designed meeting rooms in our Visitor Center. The Visitor Center with its state-of-the-art presentation devices is the perfect location to conduct training courses for customers as well as for in-house workshops. A bistro area provides our guests with a casual atmosphere that facilitates communication and relationships. In the near future, customers will be able to carry out their pre-delivery inspections on their ordered equipment directly in front of the Visitor Center.

2019CHARGER 380 - the latest innovation in towbarless aircraft tractor technology

TREPEL’s first towbarless aircraft tractor, the CHARGER 380, premiered at the ”inter airport europe” show in Munich. It is the most powerful and capable in its class, covering aircraft types up to A340-600 and B777. With oversteer protection and hydro-pneumatic suspension it combines state-of-the-art technology with superior comfort.

2019TREPEL goes electric

TREPEL’s most popular conventional pushback tractor models, the CHALLENGER 150 and 280, were presented as electric versions at the ”inter airport europe” show in Munich. They have the same aircraft range as their equivalent diesel versions.

2019NEO e-power

TREPEL’s reconceptualized electric-powered CHAMP 70We NEO was presented at the ”inter airport europe” show in Munich. Its innovative tripartite power system allows longer use of battery power and energy can be recuperated when lowering the main platform.

2019200th CHAMP 350 sold

The 200th CHAMP 350 went to LuxairGroup and the handover was celebrated in our factory in Tauberbischofsheim. With a lifting capacity of 35 tons the CHAMP 350 is the absolute champion among our CHAMPs since its introduction in 2008.

2020Pushback Training Simulator CHARIOT

TREPEL’s pushback training simulator CHARIOT was first presented at 2019’s ”inter airport europe” show in Munich. Including a simulation software, a visual system and the original TREPEL driver station, the CHARIOT is ideally fitted for significantly increasing overall training efficiency and thus reducing the risk of vehicle and aircraft damage.

2020Electric-powered CHAMP 140e

With the CHAMP 140e, TREPEL presents one of the most effective and versatile electric-powered main deck loaders on the market. TREPEL consequently continues the extension of its electric-powered equipment.

2020More NEO e-power

Following the CHAMP 70We NEO,

also the CHAMP 70S and CHAMP 70U

are now available as electric-powered NEO versions,

all including the innovative

tripartite power system.

Sales

Hagenauer Str. 42

65203 Wiesbaden

Germany

Customer Service

Hochhäuser Straße 18

97941 Tauberbischofsheim

Germany

Representatives

Find your service partner

We have a network of more than 60 partners worldwide to support you in your procurement, service and maintenance tasks. Please take a look here to find one close to your location.